Rack Dunnage

We have over 40 years of experience designing and manufacturing rack dunnage to suit your custom material handling needs.

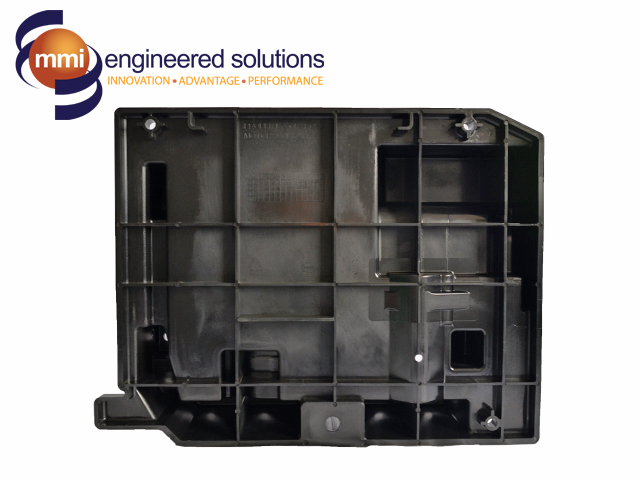

Rear Transmission Saddle

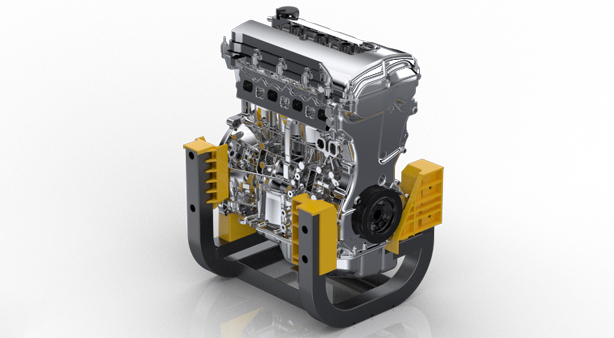

Engine Saddle

Problem:

Fully dressed engines needed to be nested and contained in Shipping Rack without being strapped to rack then shipped from the engine plant to the assembly plant without damage.

Solution:

MMI-ES engineered an engine metal Frame and Thermoplastic TPU nests that cradles the engine in the rack during transportation. The engine dunnage endures heavy impact without breaking.

Benefit:

Engines can be loaded and unloaded without the need for additional constraints saving operator time.

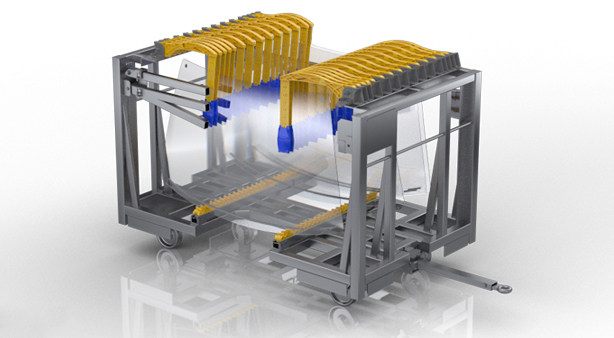

Glass Rack Windshield Transport

Problem:

Windshields/Backlights were shipped in separate racks from sequencing plants to assembly plants.

Solution:

MMI-ES engineered a rack to accommodate up to four different windshields and four different backlights.

Benefit:

Reduced the floor space at sequencing and assembly plants.