Totes

Customized To Your Needs

Custom injection molded plastic shipping and handling totes are made to your size requirements for use on gravity and powered conveyors, ASRS systems, and shipping pallets. Tote designs can include ergonomically designed handles, pin locating bosses, and card holder attachment features. Totes for machined parts can be design to use with a custom Tote Lid and TPU inserts to prevent contamination.

Sprocket Tote

Problem:

A major Tier One supplier saw significant quality issues during the shipment of sprocket assemblies. The sharp teeth from multiple configurations of assemblies were shaving the current Vac-formed and Structural Foam containers.Solution:

A newly designed tote with a lid provided the tolerances to positively engage the teeth from the sprocket assembly to eliminate movement and shaving.Benefit:

With adaptive tooling the same container could be slightly modified to safely transport over 17 variations of sprocket assemblies while eliminating contamination issues.

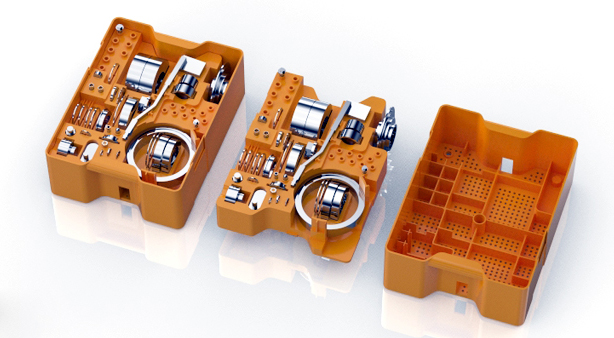

Automotive Tote

Problem:

Multiple parts for two different assemblies arrived in bulk at OEM assembly plant and were delivered to the production line in cardboard boxes. This resulted in production inefficiencies, poor ergonomics, and compromised quality.Solution:

New tray was designed to incorporate multiple components into one custom tote. Tote was engineered with a common outer tray and snap-in insert tray. Each insert contained all of the parts required for its own unique assembly. Components were nested to provide sufficient clearance for easy manual handling.Benefit:

Production efficiency is enhanced. Assembly ergonomics are improved and errors eliminated with a tray that contains all of the parts required for an assembly. Quality is improved. The OEM’s tooling investment was minimized by using a common outer tray with interchangeable inserts for both assemblies.